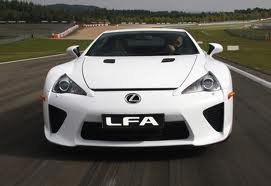

The new Lexus LFA is an important moment in the story of two Lexus and development of the supercar. A true “blade” design, Lexus LFA was created by a small engineers, and dedicated fans whose achievement has been to expand the boundaries of technology and engineering of materials at each stage of producing a car like no other has made the flagship Lexus.

Built using advanced technology of carbon fiber, are rear-wheel drive powered by a Lexus LFA measure at high speed 552bhp 4.8-liter naturally aspirated V10 engine, adapted to a rear-mounted six-speed automatic sequentially, giving 200 mph-Performance Plus.

In the words of the Chief Engineer Haruhiko Tanahashi, “The Lexus LFA is a pure racing car, a machine designed to achieve one goal – to offer a superb driving experience over the last decade, we have pushed all boundaries to pursuing this goal, and I do. think we’ve created the most driver orientated car we have. “

Carbon Fiber Construction

Keep the vehicle’s weight to an absolute minimum was one of the crucial elements in the development of the Lexus LFA and this led to the decision to use aluminum for the automotive design to advanced Carbon Fiber Reinforced Plastic (CFRP) for the chassis and body.

In addition, Lexus has decided to carbon fiber structure must be built into the house rather than through a third party vendor. In doing so, based on the heritage of Toyota Motor Corporation in fabric technology to push the limits of their technical skills, the development of new carbon fiber fabric and a laser system for monitoring the integrity of the material.

Four times the strength of aluminum, carbon fiber Lexus LFA provides an incredibly rigid and strong, and also produces great advantages of weight saving of around 100kg is equivalent to an aluminum frame. CFRP accounted for 65 percent of the body-in-white, aluminum alloy used for the remaining 35 percent.

Unlike some of the vehicles on the market that the use of CFRP construction, the Lexus LFA uses the same advanced technology to promote high-tech resin space programs of its weight and unmatched resistance properties.

ENGINE

Heart Lexus LFA is a custom-made, naturally aspirated V10 engine that sets new standards for compact, lightweight architecture and scintillating performance. From the beginning, it was decided, the engine should have a capacity of 4805 cc, developing 552bhp and crying REV 9000-rpm red line. 72 degrees between the cylinder heads is to achieve an ideal balance between the engine exceptionally smooth, the same individual, electronically controlled throttle bodies for each cylinder gives excellent throttle response.

Using a system of dry-sump lubrication allows the block can be placed deep in the engine compartment, lower center of gravity of the car and inertia, and allowing the engine to handle sustained, high-speed cornering.

V10 generates torque of 480nm at 6800 rpm, 90 percent, which is available from 3700 rpm to 9000 rpm red line, thanks to the Dual VVT-i technology, equal length exhaust manifolds, and in large quantities, 12-hole injectors. This gives a burning-in to listen to the acceleration at all speeds of the engine and transmission: a zero-62 mph in just 3.7 seconds and a top speed of 202 mph

Weighing 1480 kg, the Lexus LFA a power to weight ratio of 373bhp per tonne, while the specific power of 115bhp per liter is among the highest of any current supercar, aided by a high compression ratio 0:01, low friction optimized internal consumption and exhaust.

Despite its power, the V10 is a lesson in a compact and lightweight, about the same size as a regular V8 and weighs about as much conventional V6. It is as reliable and refined than any other energy plan Lexus and more than Euro 5.

The engine was developed in collaboration with Yamaha through the partnership established in collaboration between Toyota Motor Corporation and the Japanese specialist engineering company.

SOUND

Lexus LFA is note acoustic intake and exhaust systems are specially calibrated to provide an impressive “soundtrack”, which expresses extreme performance of the car, both outside and inside the cabin. Mentioned by the team sound like “Harmony Octave” is inspired by the sound of a Formula 1 engine at full capacity and is opposed to it, any car from the road, with different qualities harmonics created by the engine moves to the maximum 9000 rpm

BRAKES

The Lexus LFA is one of the most advanced and powerful braking and equipped with a production car that is suitable to meet the demands of its 200 miles per hour, more performance.

Disc brakes are carbon ceramic material (CCM), which is lighter, as well as provide consistency in all circumstances. The front discs are 390 mm in diameter and 34 mm thick, grabbed six-piston calipers in aluminum, rear discs measure 306 millimeters in diameter, are 28 mm thick and have four pot calipers. All use a high friction pads microns, produced exclusively for use with CCM brakes.

Exterior design

Dictated by the layout engine before the battle medium, long and short overhangs, sophisticated aerodynamics and cockpit floor, the flow of the roof lines on a windowsill Lexus LFA convex to concave transparent online. And its low weight and high strength carbon fiber reinforced (CFRP) has also given designers greater freedom to create shapes, curves and edges that would not have been possible with the metal.

Styling, however, the true principles of the L-finesse, the project presented to all current Lexus models. Form follows function, as evidenced by the number of air intakes and aerodynamic details, and even the design of the side mirrors, air-shaped channel in the back of the car to the rear access

INTERIOR

Low cabin is divided into three areas: mechanics, which involves the construction of a skeleton of the car, living man, with two seats placed at the very center of the car, and driving area, a high-tech equipment that meets the ‘driver and the car

The cabin is built by hand, with a pilot focused on ergonomics. The seats, upholstered in leather and Alcantara, offer high-quality half back and support you need for a car capable of 200 mph-plus performance. Cut the echoes of advanced materials used in the Lexus LFA structure in which the exposed areas as well as Matt and gloss carbon fiber. Trim details should be finished in brushed metal and the floor-hinged gas and brake pedals are made of forged aluminum. Like the exterior, the owners can choose from a variety of colors and details of the interior according to your taste.